Enhance workflow

,Provides timely and consistent reading times with automated plate imaging, offering flexibility to read images at different time-points per your operating protocols. This technology opens the possibility of new workflows across the incubation cycle.

,Drive standardisation

,Helps enhance bacterial growth by standardising incubation times and conditions in a controlled, closed-door environment. The BD Kiestra™ ReadA may increase bacterial growth by up to 46% compared to traditional microbiology.1

,Improve operational efficiency

,Improve your operational efficiency by automating plate sorting and distribution. Plates are automatically delivered to the appropriate incubator to begin the incubation and imaging protocol.

,Deliver accuracy

,Capture images in a standardised manner to reduce variability, improve the consistency of results and see details invisible to the human eye.

,Flexible Connectivity

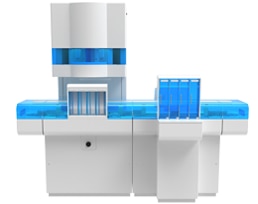

,Available as part of a track-based BD Kiestra™ laboratory automation solution or as a standalone instrument, allowing flexible options based on your laboratory’s current workflow and size.

,Input stackers

,Automate plate management with four input stackers enabling continuous loading of inoculated plates. Each stacker can be configured to a specific task, including a priority plate infeed to allow the handing of priority plates when needed

,Parallel plate processing

,Parallel plate processing with 2 infeed track to automatically move plates in and out of the incubator and imaging station to ensure continuous tasks execution especially during activity peaks.

,Closed door incubation

,Enables constant temperature and humidity at stable O2 or CO2 levels.

,Laminar air flow

,Laminar air flow stabilises conditions for every individual plate stored in the incubator minimising the chance of plates drying out.

,Standardised incubation times

,Plate protocol will direct incubation condition, incubation duration and image times.

,High throughput imaging

,High speed camera that can image up to 300 plates per hour.

,High quality plate imaging

,25-megapixel camera with a telecentric lens.

,Three different light sources

,Top, bottom and side light for optimal colony presentation on high resolution monitors.

,BD Kiestra™ Optis technology

,High-quality camera with customized optics and plate orientation to normalise and standardise images made over time and minimise variation between instruments. With 22 images taken of each plate, optimal pixels are identified for ideal image representation.

,Workflow management

,BD Synapsys™ , web-based informatics solution provides convenient access to critical information from anywhere, at any time. Whether you are a standalone lab or part of a complex network, BD Synapsys™ enables remote connections, supporting task execution and facilitating your decision-making process.

With features like an expert system, rules engines for protocol standardisation, and a customizable interface, it empowers you with precision, efficiency, and informed decision.

,Output stackers

,Automate plate management with 4 output stackers for user-configurable plate sorting including waste handling, follow-up work and offloading of plates for external incubation.